PROJECTS > INDUSTRIAL

PRECAST CONCRETE AND AUXILIARY MEANS

Auxiliary means in which the self-launching falsework stands out, the special fungiform formwork, the launching car for 200 Tm beams, cantilever cars for spans up to 175 m.

International precast concrete factories. 297,500 m3 of precast concrete. 3 international mobile production plants. 18 patents for parts and construction systems. 700 different models manufactured.

Mobile Factory, Dallas, USA

Precast concrete factory

Beam launcher, Eume

Beam launcher: auxiliary construction equipment designed for the assembly of prefabricated beams of all types, including variable edge beams, up to 50m in length

Movable scaffolding system, Giles

Movable scaffolding system: Construction auxiliary means that allows the in-situ construction of concrete slabs without the need to affect the ground and regardless of the height of the piles. Its modular composition makes it a very versatile and high-performance construction equipment, allowing an industrial process in the construction of the slabs, executing spans of up to 80m in length, both with constant and variable edge. Movable scaffolding system has been designed ad hoc for the company, so its functions are very specific and meet the highest expectations and safety conditions

Segment lifting traveller, Rande

Segment lifting traveller: Equipment used for the lifting of metal segments weighing 85 tons. By means of a system specially designed for this equipment, it allows the lifting of the pieces from the ground or the sea for their placement on the deck. Only 9 days pass from the beginning of the lifting of the piece to the concreting of the slab.

Segment lifting traveller, Chiche (Ecuador)

Segment lifting traveller: Equipment used for the execution of segments in situ by means of successive cantilevers, both in slabs and arches, it does not require the use of large cranes for the work. The industrialization of the work cycle allows the execution of a segment of up to 190 tons per week.

Wings traveller, Lindín

Construction equipment specially designed for the execution of the cantilever slabs of the deck cantilevers in cross section and the placement of prefabricated props or struts that allow the construction of single carriageway decks. Its design allows the passage of trucks through it, so that the execution of the central section of the deck can be combined with other equipment a few spans ahead, drastically reducing the execution time.

Slab traveller, San Pedro (Ecuador)

Construction auxiliary means for the execution of in-situ concrete slabs, it can work on mixed or concrete decks. It is an equipment with great capacity to adapt to the geometry of the bridge deck, and does not require machinery support from the ground, so it is independent of the height at which it works. The conventional work output is 48m of deck length per week.

Lower traveller, San Pedro

By means of a lifting system designed for this purpose, it allows the placement of parts under the deck of a bridge, loading them from the top and lowering them to their final position. In addition, it has working platforms that facilitate the location of the workers in complete safety while the work is being carried out.

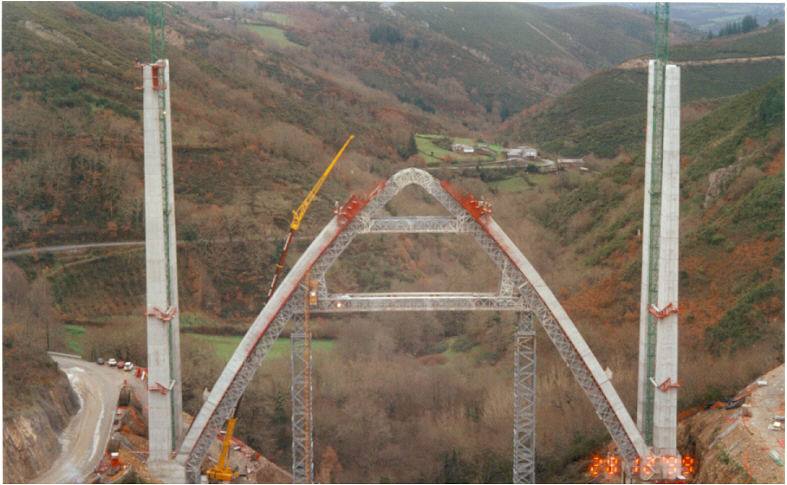

Movable scaffolding system, semi-arch lifting, shoring tower bridge formwork, Río Verde

After more than 15 arches executed using this method, we have managed to optimize the processes to the maximum by reducing their cost and increasing performance.

Self-supporting arched formwork, Narón

The formwork used in the construction of the arch was special because it consisted of two porticoes and lateral structural elements that not only supported the loads of the concreting of the arch gables, but also served as rails for the climbing of the formwork of the gables. The system was anchored by means of high-strength bars to the adjacent piers.